Next-gen Systems for Biofabrication

Aniela Hoitink, CEO and founder of NEFFA—New Fashion Factory and MYCOTEX in conversation with Natsai Audrey Chieza

LETTING GO OF DESIGN CONVENTION

Natsai Chieza: Mycelium—the dense, interconnected fungal network responsible for nutrient cycling in ecosystems—has recently caught the attention of industries as a promising leather alternative. But its potential goes far beyond imitation. By presenting mycelium simply as a leather replacement, we may have limited its true power, locking it into the same industrial mindset of mass production and standardisation. Instead of celebrating what makes mycelium unique, much of the focus has been on proving it can mimic animal leather rather than exploring the material’s distinct advantages and transformative possibilities.

Your theory of change at NEFFA offers a compelling alternative. By embracing mycelium’s biological processes and adaptability, you move beyond replication, unlocking its potential for customisation at scale and presenting a radically new vision for sustainable design.

Aniela Hoitink: Ecovative was one of the first to produce mycelium material for example as a styrofoam replacement, and naturally, many followed their lead—they proved the concept. So it was logical for many to create mycelium sheets that way eventually. While everyone was thinking about building systems based on solid-state fermentation for mycelium, I was already working in a semi-liquid state, which revealed an entirely different approach.

People think that creating sheet material is the easiest way to integrate mycelium into supply chains, but many companies are proving that it’s far more challenging than expected. What’s often overlooked is that whether you’re working with a sheet or liquid mycelium, you have to meet exact specifications. Secondly, when it comes to testing in an industrial context, you need to adapt the product manufacturing process to the material—everything from how the textile is transported to the machinery used, even down to the type of needle and stitching method. The third challenge is finding a factory willing to pause conventional production to help you scale your material. So you are waiting maybe half a year for your material to be tested in an industrial environment, which, as you know, carries its risks and takes time.

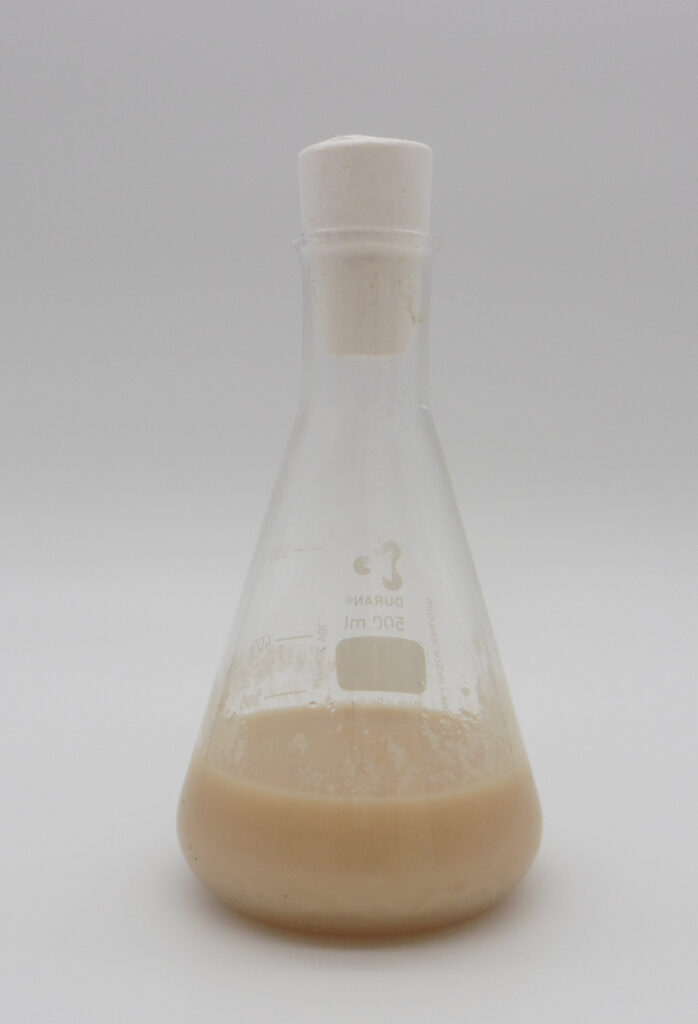

Our approach at NEFFA is to grow mycelium in liquid cultures and apply it to 3D moulds. For a lot of people, it seems more complex, but actually, this way of producing is much easier. The complexity lies in convincing people that our processes can achieve the same results.

The complexity lies in convincing people that our processes can achieve the same results.

Natsai Chieza: Your background is in commercial fashion design. How did you pivot toward biotechnology, and what did that journey look like?

Aniela Hoitink: Since my time at Art Academy, I’ve always been focused on personalisation. I’m fascinated by how the right garment—like a perfectly tailored jacket—can make you feel incredible. That’s always been my goal: to create perfectly fitted clothes. When I started my first company in 2008, I explored fashion sustainability but found it dull—garments looked like they’d been washed a hundred times, and the discussions revolved around buttons of cork. For me, sustainability has to be commercial—people need to want the product.

I began working at the intersection of technology and fashion, exploring what was happening at research institutes and universities and making it applicable to commercial fashion. I did a lot of prototyping, initially working with solar panels, LEDs, and sensors. Researchers often focus on tech capabilities, like showing a LED light can produce a million colours, but if the result looks like a Christmas tree, no one will buy it. The challenge was finding ways to make these innovations desirable—so consumers feel great wearing the garments rather than like they’re dressed for Christmas!

As I worked with various technologies and as biotechnology advanced, I began experimenting with growing skin bacteria in Petri dishes, which made me think: our skin has its own microbiological environment, so how could we nurture that? Could bacteria and microorganisms influence textiles to benefit us? In the Netherlands, we have a yellow dishcloth that we tend to leave too long before washing. So I wondered, could bacteria be integrated into textiles to signal when it’s time to wash—like turning from yellow to brown when it’s too dirty? This got me thinking about how both technology and microbiology could enhance our lives, whether in fashion or interiors.

I eventually collaborated with a professor on mycelium and became fascinated. It was a crash course—one afternoon learning how to inoculate a petri dish and grow my own. Within two years, I had a proof of concept. As a fashion designer, I started pleating mycelium by drying it on wooden sticks, but it stuck to the wood! So, I ended up with this fragile, pleated fabric that did something unexpected, but in a good way. I began wondering, if it sticks to other things, could it stick to itself? That led to my first experiment using entirely petri dishes.

For me, it’s about understanding the behaviour of materials and working with them, not against them. Even now, when my team says, “Aniela, it’s not working,” I look at it and think, okay, maybe not as intended, but how can we use this? With biotechnology, I focus on what the organism can do naturally, steering it toward creating textile products or thin materials rather than forcing it to become something like leather.

Natsai Chieza: I love the idea that our stories about what something should be often prevent us from seeing what it can be. It’s a complete mindset shift—a mental reset—in how we receive information. You almost have to become obsessively curious about everything you see and create, right? What I find so inspiring about speaking with designers who transition into biotech is that the gap between “what do you want it to be?” and “what it is” becomes much smaller. You’re already thinking about a variety of use cases that this behaviour could address rather than feeling confined by a specific goal like tackling the leather market.

Aniela Hoitink: The research into mycelium products actually started as a solution for my own home, which was very damp. I wanted a wall hanging that could absorb moisture, so I envisioned a beautiful piece that would prevent a fungi problem—using fungi to stop fungi! This approach is something I learned a lot at Art Academy: you begin with one idea, but through discovery, you often end up somewhere entirely different. In my case, I learned from the material itself, allowing it to guide me rather than forcing my original concept. This journey ultimately led to my personal future goal: creating on-demand consumer products—what I see as the holy grail.

COMPOSING MATERIALS FOR CUSTOMISATION AND AUTOMATION

Natsai Chieza: It’s really fascinating, and this leads me to my next question on fabrication and materiality. Can you tell me more about the role automation plays in your manufacturing method?

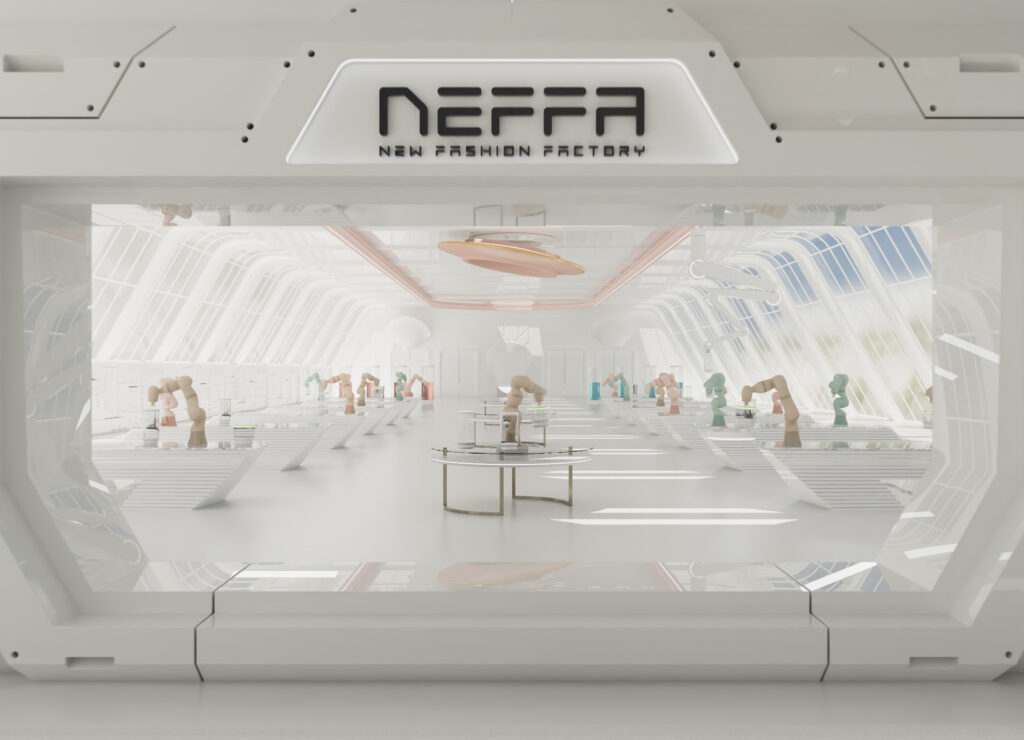

Aniela Hoitink: We grow mycelium in a bioreactor under specific conditions. Our technology is then used to apply this biomass to digitally fabricated 3D moulds, adding ingredients as needed. Our goal is to streamline production, going from material to final product as quickly as possible. For this, we use robotics to automate the process, ensuring stability by minimising human intervention. Interestingly, simplifying the process—removing steps while maintaining the same result—is more challenging than adding complexity.

Natsai Chieza: The digital customisation of the material is extremely apparent—it’s rare to see such aesthetic qualities in mycelium products contrasting the digital and machine with the human and more-than-human. What applications do you envision for this material, and which ones are you actively pursuing due to its unique qualities and the way you’re processing it?

Aniela Hoitink: The material lends itself to interiors, wall panels, and lighting because of its translucency, and beyond the textiles, there’s great potential for automotive dashboards and side panel interiors. With our continued R&D we also see opportunities in apparel and, eventually, footwear. When we showed at Salone in Milan this year, we showcased high-fidelity prototypes so that people would get inspired and see for themselves what they could be rather than us dictating what they should be. We don’t only work with ready-made products, but we also develop new ideas with companies if it’s something we haven’t done before. Once the client has approved the mould, this is where we start testing the intrinsic patterns or shapes.

Natsai Chieza: You’ve mentioned the opportunities to work with liquid culture, where moulding plays a crucial role in the customisation process. Could you tell us more about what sets this approach apart in the growing field of mycelium applications?

Aniela Hoitink: Our design-led solution working with 3D moulds is a holistic response to highly complex supply chains in industries like fashion—where materials and garments are transported between several different countries with, on average, seven steps. [t. - 1] We’re reducing that to just two. And as a result, we’re able to create unique products that you can’t achieve with sheet material. I think it’s good to understand when we’re talking about comparison with Ecovative or another mycelium manufacturer—they are playing an important role, I’m not against what they’re doing—they can meet the current demand because everyone thinks that we have a material problem. We just don’t think we have a material problem. We think we have a supply chain problem.

And it’s super interesting; principally, it’s not solid state versus liquid state [t. - 2] —because there are also companies working with liquid state trying to create sheet material. It’s more that we have a completely different perspective on the industry and how we see it evolving. For us, liquid culturing was actually a very logical step because, on the one hand, it has already been scaled—this meant we could work with external parties and not have to invest in development—and secondly, the liquid state can be used for 3D moulding where the structure of sheet mycelium (which bonds the mycelium together) would be harmed.

Natsai Chieza: So by making this a supply chain problem rather than a material problem, i.e. re-defining the question, you are able to develop a completely novel approach to the production of materials and products.

Aniela Hoitink: That’s right! Our goal isn’t to replace existing materials but to introduce a new manufacturing method. We are offering an innovative, sustainable alternative alongside traditional processes like cutting, sewing, and knitting—by letting go of conventional approaches. Working with 3D moulds, products can be seamless, and textures or pleats can be implemented digitally into the moulds, eliminating the need for secondary processing. While we hope to reduce some of the harmful environmental and social impacts of the current industry, we recognise that we’ll likely be adding to it as well. As effective as we may become, we won’t replace materials like cotton or traditional wovens. Instead, we want to offer a method that stands apart, producing unique products that couldn’t be made through conventional means.

“If Givenchy wants to biofabricate something, it’s going to have very different demands from what Alaia might do with the same technology. Our role as designers operating at this nexus is to create systems that are flexible and open, allowing diverse approaches to experimentation and innovation.”

DEPLOYING ADAPTIVE MANUFACTURING SYSTEMS

Natsai Chieza: Talk to me about how you’re thinking about scale at NEFFA.

Aniela Hoitink: We’ve set an ambitious goal: to have around 200 manufacturers working with our technology. We want to deploy a decentralised model that we pilot in Europe and work towards distributing across other continents. The good thing about working with digital fabrication is that you can send your digital files anywhere, while automation means your robotic infrastructure can do the same thing everywhere. When you order a hundred pieces from China, ideally, you want them made locally. Similarly, a factory in the US could be producing the same number of pieces for its local market. For me, scaling up is really about decentralisation. To achieve this, we need partners who are willing to collaborate with us to scale up the biomass, the robotic systems and the manufacturing process.

Natsai Chieza: With this model, you can either meet expectations for the product to be consistent and globally available or, by integrating digital and biological fabrication—leveraging the variability that biodiversity offers—use bioregional inputs to create context-specific solutions.

Aniela Hoitink: In my experience working in fashion, we often saw collections adapted to different regions—taste in Asia varies slightly from the US and Europe, for instance. So, from that perspective, you could have the same design tailored for different markets. I’m not a trained microbiologist; I’m a trained fashion designer with over 25 years in the industry. I’m proud of the unique approach that my background helps us bring to the table.

Natsai Chieza: I agree entirely, and it’s something that can never be overstated. When I started my career in this field, I worked part-time at a luxury department store in London to fund my research—there were no grants for people like us!

Aniela Hoitink: I’ve been there too!

Natsai Chieza: I’d walk the shop floor, serving customers with forensic knowledge about the differences between each brand’s lining, tailoring and idiosyncrasies around cut and fit. You looked at a customer and knew exactly what to recommend they try on and that sometimes the clues lay in the mood they were in. I paid attention to this, realising that whatever I was doing in the lab had to reflect both quantitative and qualitative variables of the consumer landscape. If Givenchy wants to biofabricate something, it’s going to have very different demands from what Alaia might do with the same technology. Our role as designers operating at this nexus is to create systems that are flexible and open, allowing diverse approaches to experimentation and innovation. That’s why your focus on the system rather than drop-in replacement is a radical and compelling one.

Aniela Hoitink: Flexibility is key, and one advantage of being a startup is that we can remain adaptable. We’ve designed our entire manufacturing process to be flexible, but it’s more than just the process—flexibility has to be a mindset for the whole company. There are different ways of looking at this but for us, the manufacturing process is key. Right now, we’re working with mycelium because that’s how we’ve developed our systems. But eventually, we’re open to collaborating with other material developers to adapt our supply chain, so we don’t want to limit ourselves to mycelium alone. For example, during a presentation, someone working with nylon 66 expressed interest in using our technology. For us, it’s about expanding to work with various materials, whether that’s different types of mycelium or other semi-liquid materials like algae or kombucha. As long as it’s semi-liquid, we’re open to experimenting.

We must also be ready to pivot. We’ve been examining how textile fibre pollution is as big of an issue as plastic pollution in the ocean. In 10 years’ time, our approach to sustainability might look completely different, and the materials we’re developing now for the current supply chain may need to be rethought entirely to address new needs. That’s why the steps we’re taking as a team must remain flexible. Nobody knows what the future holds, but the one thing we can be certain of is that things will change, so we should be designing for change.